A cutting tool provides a tool life of 60 minutes while machining with the cutting speed of 60 m/min. When the same tool is used for machining the same material, it provides a tool life of 10 minutes for a cutting speed of 100 m/min. If the cutting speed is changed to 80 m/min for the same tool and work material combination, the tool life computed using Taylor’s tool life model is _______ minutes (rounded off to 2 decimal places).

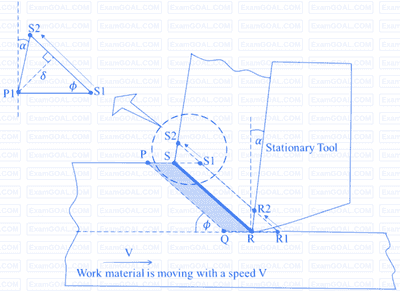

In an ideal orthogonal cutting experiment (see figure), the cutting speed V is 1 m/s, the rake angle of the tool α = 5°, and the shear angle, 𝜙, is known to be 45°.

Applying the ideal orthogonal cutting model, consider two shear planes PQ and RS close to each other. As they approach the thin shear zone (shown as a thick line in the figure), plane RS gets sheared with respect to PQ (point R1 shears to R2, and S1 shears to S2).

Assuming that the perpendicular distance between PQ and RS is 𝛿 = 25 μm, what is the value of shear strain rate (in s-1 ) that the material undergoes at the shear zone?

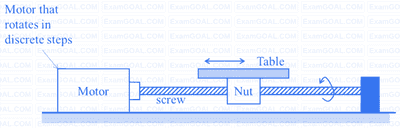

A CNC machine has one of its linear positioning axes as shown in the figure, consisting of a motor rotating a lead screw, which in turn moves a nut horizontally on which a table is mounted. The motor moves in discrete rotational steps of 50 steps per revolution. The pitch of the screw is 5 mm and the total horizontal traverse length of the table is 100 mm. What is the total number of controllable locations at which the table can be positioned on this axis?

The atomic radius of a hypothetical face-centered cubic (FCC) metal is (√2/10) nm. The atomic weight of the metal is 24.092 g/mol. Taking Avogadro’s number to be 6.023 × 1023 atoms/mol, the density of the metal is ____________ kg/m3 .

(Answer in integer)