Metal Forming · Production Engineering · GATE ME

Marks 1

$$P:$$ Strain

$$Q:$$ Strength of the work material

$$R:$$ Roll diameter

$$S:$$ Roll velocity

$$T:$$ Coefficient of friction between roll and work.

Marks 2

Wire drawing operation is performed on a perfectly plastic metal without any strain hardening. Assuming no friction and no redundant work, the maximum possible percentage reduction in area in a single pass is closest to

A steel sample with 1.5 wt.% carbon (no other alloying elements present) is slowly cooled from 1100 °C to just below the eutectoid temperature (723 °C). A part of the iron-cementite phase diagram is shown in the figure. The ratio of the pro-eutectoid cementite content to the total cementite content in the microstructure that develops just below the eutectoid temperature is ________.

(Rounded off to two decimal places)

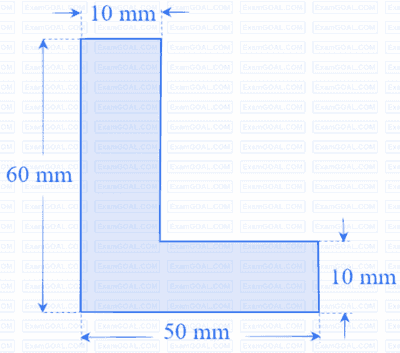

A cylindrical billet of 100 mm diameter and 100 mm length is extruded by a direct extrusion process to produce a bar of L-section. The cross sectional dimensions of this L-section bar are shown in the figure. The total extrusion pressure (p) in MPa for the above process is related to extrusion ratio (r) as

$\rm p=K_s σ_m\left[0.8+1.5\ ln(r)+\frac{2l}{d_0}\right] $

where σm, is the mean flow strength of the billet material in MPa, l is the portion of the billet length remaining to be extruded in mm, d0 is the initial diameter of the billet in mm, and Ks is the die shape factor.

If the mean flow strength of the billet material is 50 MPa and the die shape factor is 1.05, then the maximum force required at the start of extrusion is _______ kN (round off to one decimal place).

When $$\varepsilon $$ is true strain. The Young's modulus of elasticity of the material is $$200$$ $$GPa.$$ A block of thickness $$100$$ $$mm$$ made of this material is compressed to $$95$$ $$mm$$ thickness and then the load is removed. The final dimension of the block (in $$mm$$) is ____________