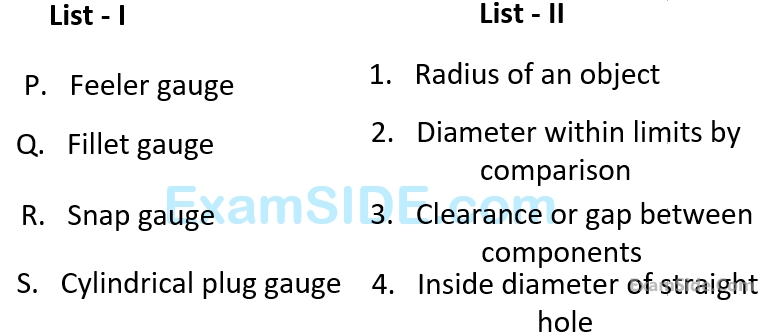

Metrology and Inspection · Production Engineering · GATE ME

Marks 1

A shaft of diameter $25^{-0.04}_{-0.07}$ mm is assembled in a hole of diameter $25^{+0.02}_{-0.00}$ mm. Match the allowance and limit parameter in Column I with its corresponding quantitative value in Column II for this shaft-hole assembly.

|

Allowance and limit parameter (Column I) |

Quantitative value (Column II) |

||

|

P. |

Allowance |

1. |

0.09 mm |

|

Q. |

Maximum clearance |

2. |

24.96 mm |

|

R. |

Maximum material limit for hole |

3. |

0.04 mm |

|

|

|

4. |

25.0 mm |

Electrochemical machining operations are performed with tungsten as the tool, and copper and aluminum as two different workpiece materials. Properties of copper and aluminum are given in the table below.

$$ \begin{array}{|c|c|c|c|} \hline \text { Material } & \begin{array}{l} \text { Atomic mass } \\ \text { (amu) } \end{array} & \text { Valency } & \text { Density }\left(\mathrm{g} / \mathrm{cm}^3\right) \\ \hline \text { Copper } & 63 & 2 & 9 \\ \hline \text { Aluminum } & 27 & 3 & 2.7 \\ \hline \end{array} $$Ignore overpotentials, and assume that current efficiency is 100% for both the

workpiece materials. Under identical conditions, if the material removal rate (MRR) of copper is 100 mg/s, the MRR of aluminum will be ________________ mg/s (round-off to two decimal places).

The minimum clearance in the assembly will be

The maximum interference (in microns) in the assembly is

Marks 2

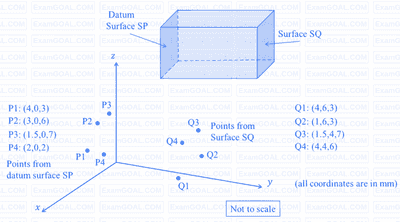

A coordinate measuring machine (CMM) is used to determine the distance between Surface SP and Surface SQ of an approximately cuboidal shaped part. Surface SP is declared as the datum as per the engineering drawing used for manufacturing this part. The CMM is used to measure four points P1, P2, P3, P4 on Surface SP, and four points Q1, Q2, Q3, Q4 on Surface SQ as shown. A regression procedure is used to fit the necessary planes.

The distance between the two fitted planes is ___________ mm.

(Answer in integer)

An optical flat is used to measure the height difference between a reference slip gauge A and a slip gauge B. Upon viewing via the optical flat using a monochromatic light of wavelength 0.5 µm, 12 fringes were observed over a length of 15 mm of gauge B. If the gauges are placed 45 mm apart, the height difference of the gauges is ______________ μm.

(Answer in integer)

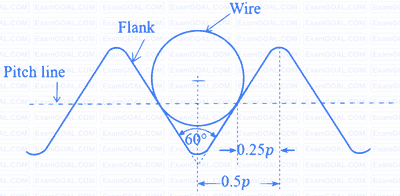

The best size wire is fitted in a groove of a metric screw such that the wire touches the flanks of the thread on the pitch line as shown in the figure. The pitch (p) and included angle of the thread are 4 mm and 60°, respectively. The diameter of the best size wire is _________ mm (round off to 2 decimal places).

$${2.0^{ \pm 0.005}}\,\,mm$$. Neglecting the gauge tolerance, the diameter (in $$mm,$$ up to $$3$$ decimal points accuracy) of the $$GO$$ ring gauge to inspect the plated pin is ___________

If the wavelength of light used to get a fringe spacing of $$1$$ $$mm$$ is $$450$$ $$nm,$$ the wavelength of light (in $$nm$$) to get a fringe spacing of $$1.5$$ $$mm$$ is ________________________.

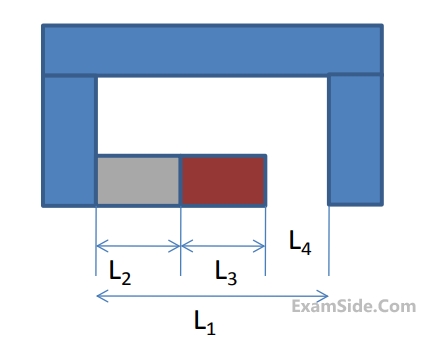

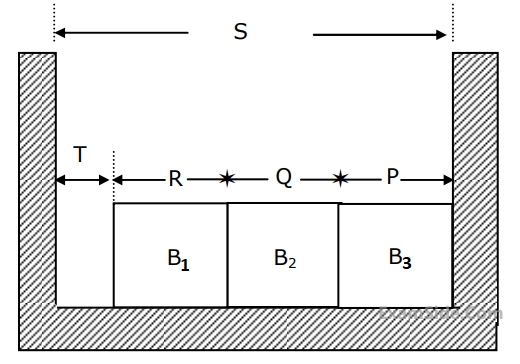

$$\eqalign{ & {L_1} = {22.0^{ \pm 0.01}}\,\,mm, \cr & {L_2} = {L_3} = {10.0^{ \pm 0.005}}\,\,mm, \cr} $$

Assuming the normal distributions of part dimensions, the dimension $${L_4}$$ in $$mm$$ for assembly condition would be,

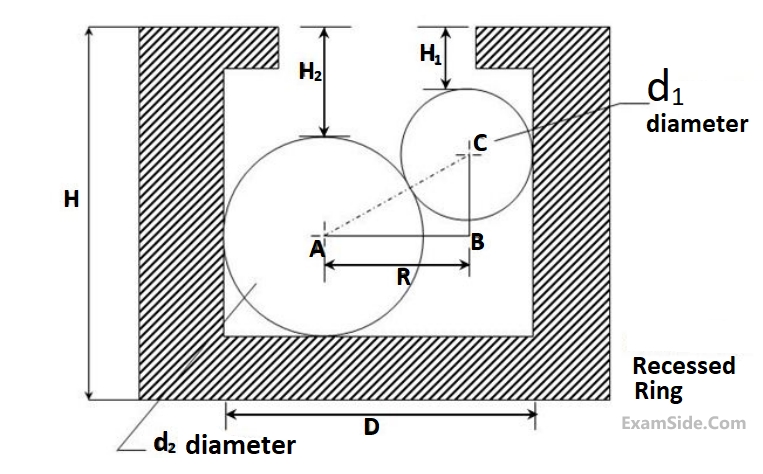

The distance $${H_2} = 35.55\,\,mm$$ and $${H_1} = 20.55\,\,mm$$. The diameter ($$D,$$ in $$mm$$) of the ring gauge is __________________.

Use the following data:

Diameter $$60$$ lies in the diameter step of $$50-80$$ $$mm$$

Fundamental tolerance unit, $$i,$$ in $$\mu m = 0.45\,\,{D^{1/3}} + 0.001D,$$

where $$D$$ is the representative size in $$mm;$$ Tolerance value for $${\rm I}T8 = 25i,$$ Fundamental deviation for $$'‘f’'$$ shaft $$ = - 5.5{D^{0.41}}$$

If $${R_p} = {R_Q} > 0,$$ which one of the following would be consistent with the observation?

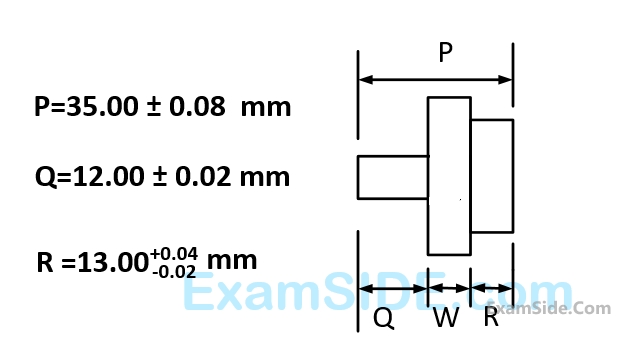

With $$100\% $$ confidence, the resultant dimension $$W$$ will have the specification

The maximum eccentricity of the bush, in $$mm$$ will be