Casting · Production Engineering · GATE ME

Marks 1

The allowance provided to a pattern for easy withdrawal from a sand mold is

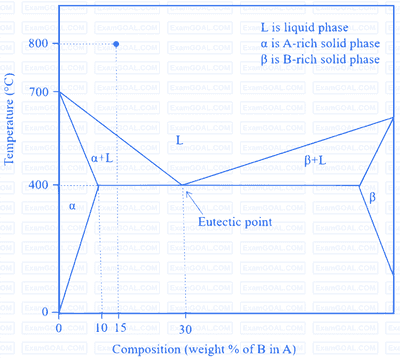

Fluidity of a molten alloy during sand casting depends on its solidification range. The phase diagram of a hypothetical binary alloy of components A and B is shown in the figure with its eutectic composition and temperature. All the lines in this phase diagram, including the solidus and liquidus lines, are straight lines. If this binary alloy with 15 weight % of B is poured into a mould at a pouring temperature of 800 °C, then the solidification range is

(Thermal conductivities of steel, copper and aluminum are $$60.5, 401$$ and $$237$$ $$W/m$$-$$K,$$ respectively. Specific heats of steel, copper and aluminum are $$434, 385$$ and $$903$$ $$J/kg$$-$$K,$$ respectively. Densities of steel, copper and aluminum are $$7854, 8933$$ and $$2700$$ $$kg/{m^3},$$ respectively.)

Marks 2

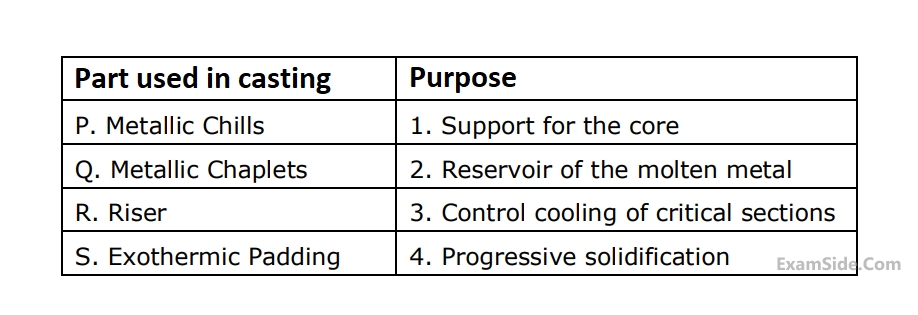

$$ \text { Match the mold elements in the casting process with the most suitable function } $$

| Column I | Column II | ||

|---|---|---|---|

| P. | Blind riser |

I. | Casting with internal cavity |

| Q. | Chill |

II. | Molten metal reservoir |

| R. | Skim bob |

III. | Nucleating agent |

| S. | Core |

IV. | Assisting in faster heat removal from melt |

| T. | Insulating sleeve |

V. | Removal of impurities |

| U. | Inoculant | VI. | Increasing the solidification time |

Two metal parts (a cylinder and a cube) of same volume are cast under identical conditions. The diameter of the cylinder is equal to its height. The ratio of the solidification time of the cube to that of the cylinder is ___________ (rounded off to 2 decimal places).

Assume that solidification time follows Chvorinov's rule with an exponent of 2 .

Aluminium is casted in a cube-shaped mold having dimensions as 20 mm × 20 mm × 20 mm. Another mold of the same mold material is used to cast a sphere of aluminium having a diameter of 20 mm. The pouring temperature for both cases is the same. The ratio of the solidification times of the cube-shaped mold to the spherical mold is _______ (answer in integer).

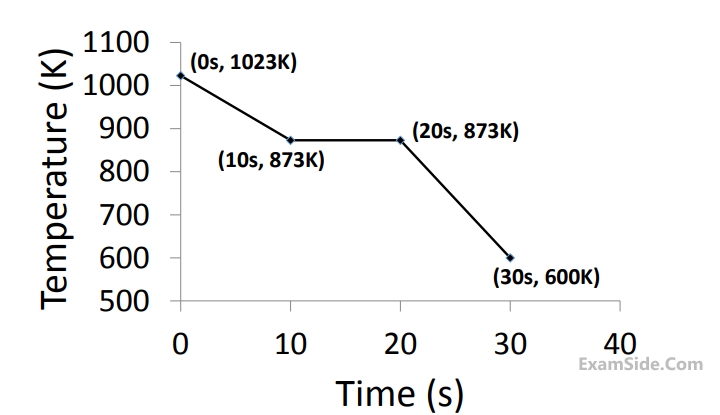

Assuming uniform temperature throughout the volume of the metal during solidification, the latent heat of fusion of the metal (in $$kJ/kg$$) is ______________

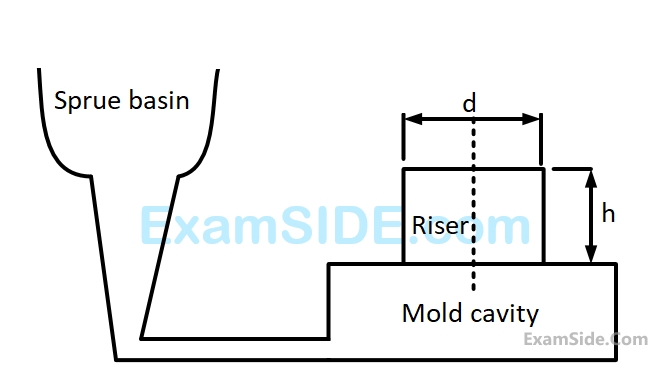

$$25cm \times 15cm \times 5cm$$ steel casting are to be determined. For the tabulated shape factor values given below, the diameter of the riser (in $$cm$$) is _______________

Marks 4

Marks 5

Assume

(a) constant temperature,

(b) no loss in the velocity head and

(c) diameter of gate $$=8$$ times diameter at the sprue base.

Properties of the molten metal are $$\gamma = 0.9\,\,m{m^2}$$ per second, $$\rho = 700\,\,kg/{m^3},$$ & $${C_p} = 33.6\,\,J/mol$$-$$K.$$ The diameter of sprue to avoid aspiration effect.