Marks 1

Marks 2

Parts P1 - P7 are machined first on a milling machine and then polished at a separate machine. Using the information in the following table, the minimum total completion time required for carrying out both the operations for all 7 parts is _______ hours.

|

Part |

Milling (hours) |

Polishing (hours) |

|

P1 |

8 |

6 |

|

P2 |

3 |

2 |

|

P3 |

3 |

4 |

|

P4 |

4 |

6 |

|

P5 |

5 |

7 |

|

P6 |

6 |

4 |

|

P7 |

2 |

1 |

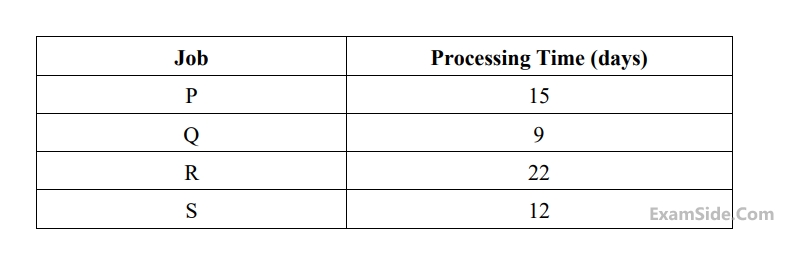

If the Earliest Due Date $$(EDD)$$ rule is used to sequence the jobs, the number of jobs delayed is

Using the Shortest Processing Time $$(SPT)$$ rule, total tardiness is

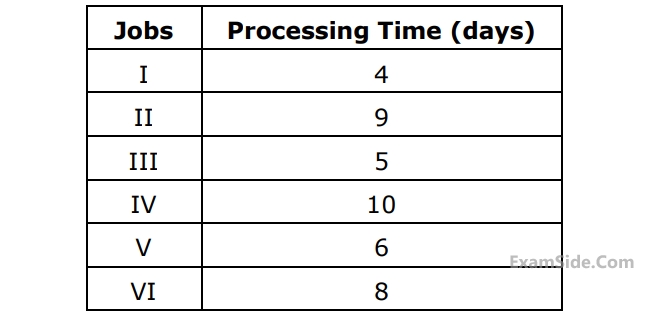

Average flow time (in days) for the above jobs using Shortest Processing Time rule is

A schedule that minimizes the total inventory cost is

Marks 5

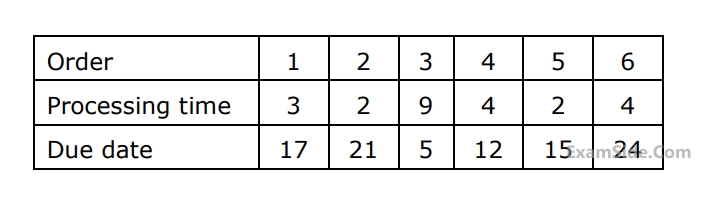

Assume that all orders are ready for processing. Give a production schedule that minimizes the average flow time. Compare this schedule with one that minimizes tardiness (lateness).

Which schedule will minimize the total cost?

What is the minimum total cost?

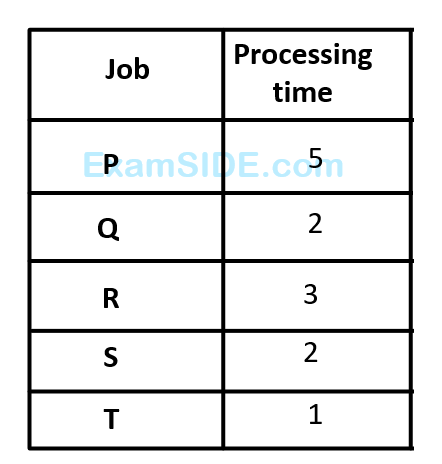

Which jobs (if any) fail to meet their due dates?

Considering mean lateness and mean flow time, evaluate the shortest-time rule and least-slack rule and recommend the desirable rule.