1

GATE ME 2001

MCQ (Single Correct Answer)

+2

-0.6

During orthogonal cutting of mild steel with a $$10$$ degrees rake angle tool the chip thickness ratio was obtained as $$0.4.$$ The shear angle (in degrees) evaluated from this data is

2

GATE ME 2001

MCQ (Single Correct Answer)

+2

-0.6

For turning $$NiCr$$ alloy steel at cutting speeds of $$64m/min$$ and $$100m/min,$$ the respective tool lives are $$15min$$ and $$12$$ $$min.$$ The tool life for a cutting speed of $$144m/min$$ is

3

GATE ME 2000

MCQ (Single Correct Answer)

+2

-0.6

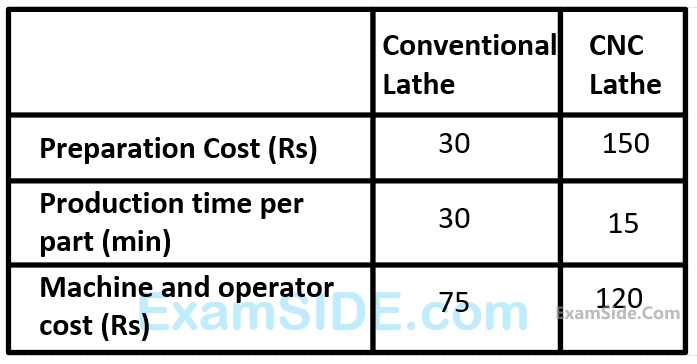

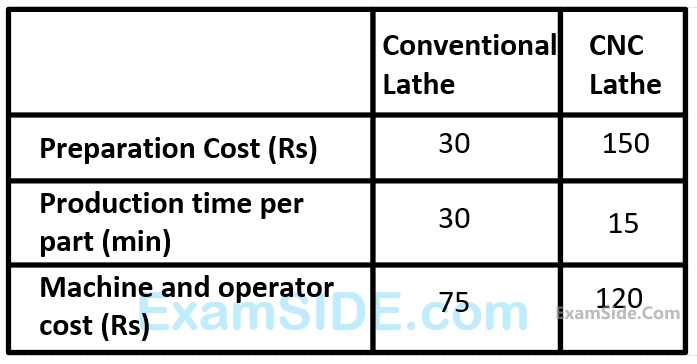

A conventional lathe and a $$CNC$$ lathe are under consideration for machining a given part. The relevant data are shown below :

The machine preferred for producing $$100$$ pieces is

4

GATE ME 1999

MCQ (Single Correct Answer)

+2

-0.6

What is the approximate $$\% $$ change in the life, $$t,$$ of the tool with zero rake angle used in orthogonal cutting when its clearance angle, $$\alpha ,$$ is changed from $$10$$ to $$7$$ deg?

(Hint: flank wear rate is proportional to $$\cot \,\alpha $$)

Questions Asked from Metal Cutting (Marks 2)

Number in Brackets after Paper Indicates No. of Questions

GATE ME 2024 (1)

GATE ME 2023 (3)

GATE ME 2022 Set 2 (2)

GATE ME 2022 Set 1 (2)

GATE ME 2017 Set 2 (2)

GATE ME 2017 Set 1 (1)

GATE ME 2016 Set 1 (1)

GATE ME 2016 Set 3 (2)

GATE ME 2016 Set 2 (1)

GATE ME 2015 Set 2 (1)

GATE ME 2015 Set 1 (1)

GATE ME 2015 Set 3 (1)

GATE ME 2014 Set 1 (1)

GATE ME 2014 Set 4 (1)

GATE ME 2014 Set 3 (1)

GATE ME 2013 (3)

GATE ME 2011 (1)

GATE ME 2010 (1)

GATE ME 2009 (2)

GATE ME 2008 (3)

GATE ME 2007 (5)

GATE ME 2006 (3)

GATE ME 2005 (2)

GATE ME 2004 (1)

GATE ME 2003 (1)

GATE ME 2001 (2)

GATE ME 2000 (1)

GATE ME 1999 (1)

GATE ME 1998 (1)

GATE ME 1997 (2)

GATE ME 1989 (1)

GATE ME 1988 (1)

GATE ME Subjects

Engineering Mechanics

Machine Design

Strength of Materials

Heat Transfer

Production Engineering

Industrial Engineering

Turbo Machinery

Theory of Machines

Engineering Mathematics

Fluid Mechanics

Thermodynamics

General Aptitude