Sheet Metal Forming Processes · Production Engineering · GATE ME

Marks 1

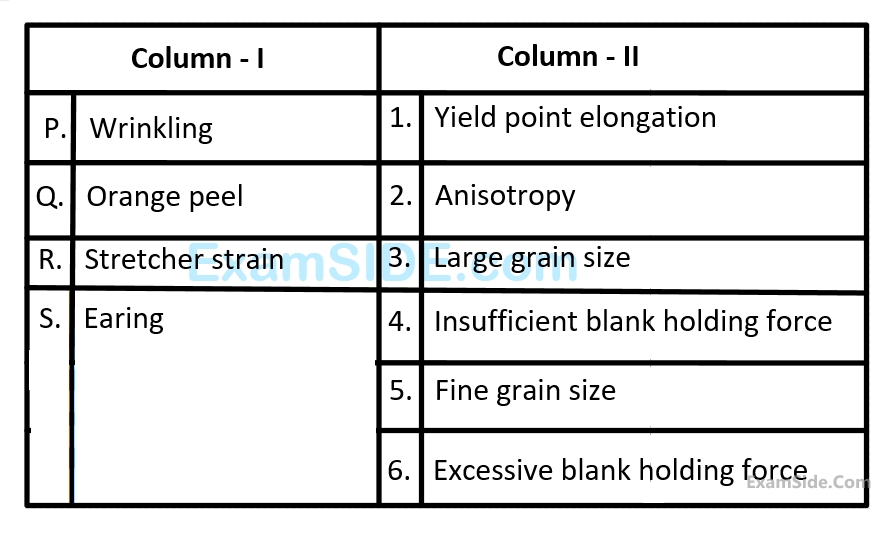

The "Earing" phenomenon in metal forming is associated with

Marks 2

A blanking operation is performed on C20 steel sheet to obtain a circular disc having a diameter of 20 mm and a thickness of 2 mm. An allowance of 0.04 is provided. The punch size used for the operation is _______ mm (rounded off to 2 decimal places).

A part, produced in high volumes, is dimensioned as shown. The machining process making this part is known to be statistically in control based on sampling data. The sampling data shows that D1 follows a normal distribution with a mean of 20 mm and a standard deviation of 0.3 mm, while D2 follows a normal distribution with a mean of 35 mm and a standard deviation of 0.4 mm. An inspection of dimension C is carried out in a sufficiently large number of parts.

To be considered under six-sigma process control, the upper limit of dimension C should be ____________ mm.

(Rounded off to one decimal place)

A 4 mm thick aluminum sheet of width w = 100 mm is rolled in a two-roll mill of roll diameter 200 mm each. The workpiece is lubricated with a mineral oil, which gives a coefficient of friction, μ = 0.1. The flow stress (σ) of the material in MPa is σ = 207 + 414 𝜀, where 𝜀 is the true strain. Assuming rolling to be a plane strain deformation process, the roll separation force (F) for maximum permissible draft (thickness reduction) is _________ kN (round off to the nearest integer).

Use:

$F = 1.15 \barσ \left( 1 + \frac{\mu L}{2 \bar h} \right)$ wL, where $\bar \sigma$ is average flow stress, L is roll-workpiece contact length, and $\bar h$ is the average sheet thickness

Size of the blank $$25$$ $$mm$$

Thickness of the sheet $$2$$ $$mm$$

Radial clearance between punch and die $$0.06$$ $$mm,$$ Die allowance $$0.05$$ $$mm$$

Assuming force $$Vs$$ displacement curve to be rectangular, the work done in $$J$$ is

A shear of $$20mm$$ $$(S=20mm)$$ is now provided on the blade. Assuming force $$Vs$$ displacement curve to be trapezoidal, the maximum force (in $$kN$$) exerted is