GATE ME

Where $$S$$ is the sphere, $$\,\,{x^2} + {y^2} + {z^2} = 1\,\,$$ and $$n$$ is the outward unit normal vector to the sphere. The value of the surface integral is

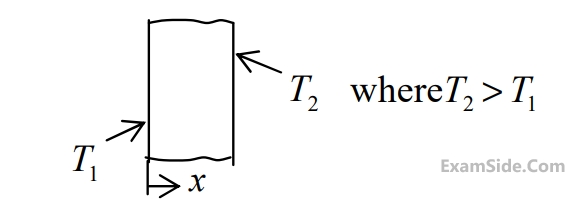

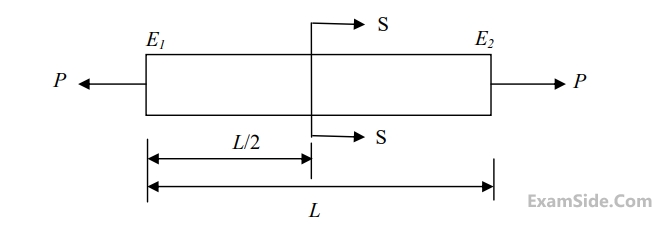

As $$x$$ increases, the state temperature gradient $$(dT/dx)$$ will

If $${q_w}$$ $$=2500x,$$ where $$x$$ is $$m$$ and in the direction of flow ($$x=0$$ at the inlet), the bulk mean temperature of the water leaving the pipe in $$^ \circ C$$ is

If $${q_w}$$ $$=5000$$ and the convection heat transfer coefficient at the pipe outlet is $$1000$$ $$W/{m^2}K,$$ the temperature in $$^ \circ C$$ at the inner surface of the pipe at the outlet is

$$\eqalign{ & Maximize\,\,\,\,3x + 7y \cr & Subject\,\,to\,\,\,3x + 7y \le 10 \cr & \,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,4x + 6y \le 8 \cr & \,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,x,\,\,y \ge 0 \cr} $$

It has ..............

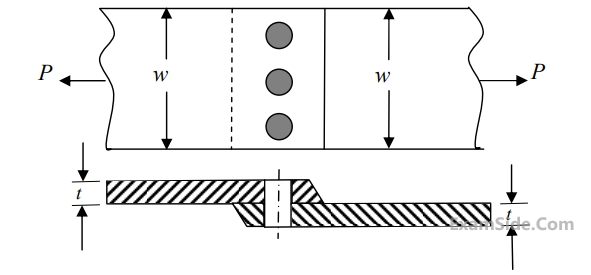

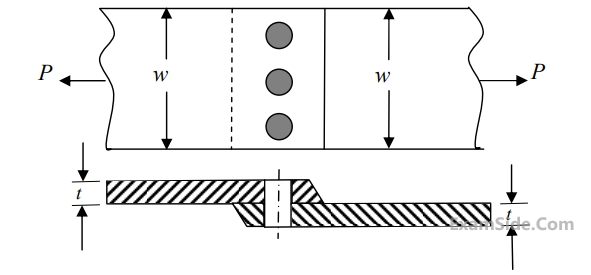

width of the plate $$w = 200$$ $$mm,$$ thickness of the plate $$t = 5$$ $$mm,$$ number of rivets $$n = 3,$$ diameter of the rivet $${d_r} = 10\,\,\,mm,$$ diameter of the rivet hole $${d_h} = 11\,\,\,mm,$$ allowable tensile stress of the plate $${\sigma _p} = 200\,\,MPa,$$ allowable shear stress of the rivet $${\sigma _s} = 100\,\,MPa$$ and allowable bearing stress of the rivet $${\sigma _c} = 150\,\,MPa.$$

If the rivets are to be designed to avoid crushing failure, the maximum permissible load $$P$$ in $$k/N$$ is

width of the plate $$w = 200$$ $$mm,$$ thickness of the plate $$t = 5$$ $$mm,$$ number of rivets $$n = 3,$$ diameter of the rivet $${d_r} = 10\,\,\,mm,$$ diameter of the rivet hole $${d_h} = 11\,\,\,mm,$$ allowable tensile stress of the plate $${\sigma _p} = 200\,\,MPa,$$ allowable shear stress of the rivet $${\sigma _s} = 100\,\,MPa$$ and allowable bearing stress of the rivet $${\sigma _c} = 150\,\,MPa.$$

If the plates are to be designed to avoid tearing failure, the maximum permissible load $$P$$ in $$kN$$ is

$$\eqalign{ & \,\,\,\,\,\,\,\,\,\,\,\,Carbi{\mathop{\rm de}\nolimits} \,\,tool:\,\,\,\,\,\,\,\,\,\,\,\,V{T^{1.6}} = 3000 \cr & \,\,\,\,\,\,\,\,\,\,\,\,HSS\,\,tool:\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,V{T^{0.6}} = 200 \cr} $$

Where $$V$$ is the cutting speed in $$m/min$$ and $$T$$ is the tool life in $$min.$$ The carbide tool will provide higher tool life if the cutting speed in $$m/min$$ exceeds

The normal force acting at the chip-tool interface in $$N$$ is

The orthogonal rake angle of the cutting tool in degrees is

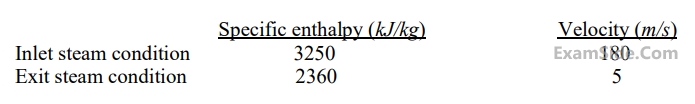

The rate of heat loss from the turbine per $$kg$$ of steam flow rate is $$5$$ $$kW.$$ Neglecting changes in potential energy of steam, the power developed in $$kW$$ by the steam turbine per $$kg$$ of steam flow rate, is