1

GATE PI 2008

MCQ (Single Correct Answer)

+2

-0.6

In an orthogonal cutting experiment, an $$HSS$$ tool having the following tool signature in the orthogonal reference system $$(ORS)$$ has been used: $$0-10-7-7-10-75-1$$

Given : Width of cut $$=3.6mm;$$

Shear strength of work piece material $$460N/m{m^2};$$

Depth of cut $$=0.25mm;$$

Coefficient of friction at chip tool interface $$=0.7.$$

Given : Width of cut $$=3.6mm;$$

Shear strength of work piece material $$460N/m{m^2};$$

Depth of cut $$=0.25mm;$$

Coefficient of friction at chip tool interface $$=0.7.$$

Shear plane angle (in degrees) for minimum cutting force is

2

GATE PI 2008

MCQ (Single Correct Answer)

+2

-0.6

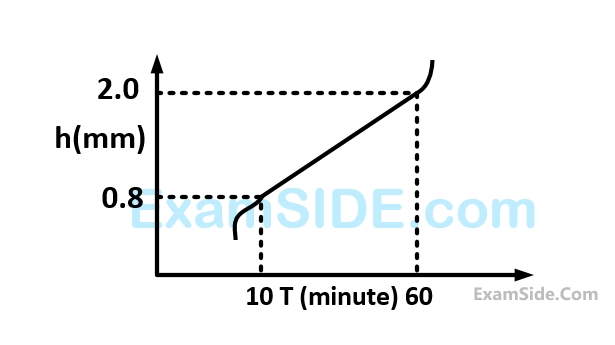

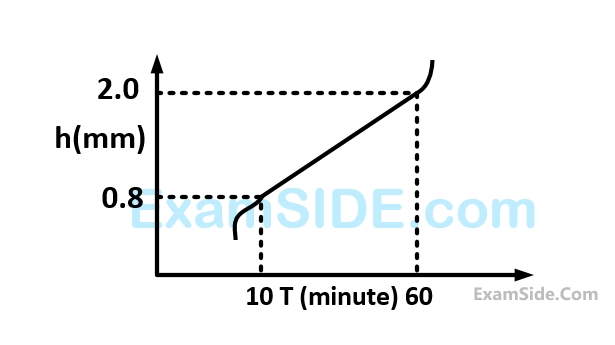

During machining, the wear land $$(h)$$ has been plotted against machining time $$(T)$$ as given in the following figure.

For a critical wear land of $$1.8mm,$$ the cutting tool life (in $$min$$) is

3

GATE PI 2008

MCQ (Single Correct Answer)

+2

-0.6

Brittle materials are machined with tools having zero or negative rake angles because it

4

GATE PI 2007

MCQ (Single Correct Answer)

+2

-0.6

In an orthogonal cutting test, the following observations were made

Cutting force $$=1200N ;$$ Thrust force $$=500N$$

Tool rake angle $$=zero ;$$ Cutting speed $$=1$$ $$m/s,$$

Depth of cut $$=0.8mm;$$

Chip thickness $$=1.5$$ $$mm$$

Cutting force $$=1200N ;$$ Thrust force $$=500N$$

Tool rake angle $$=zero ;$$ Cutting speed $$=1$$ $$m/s,$$

Depth of cut $$=0.8mm;$$

Chip thickness $$=1.5$$ $$mm$$

Chip speed along the tool rake face will be

Questions Asked from Metal Cutting (Marks 2)

Number in Brackets after Paper Indicates No. of Questions

GATE PI Subjects

Engineering Mechanics

Strength of Materials

Theory of Machines

Engineering Mathematics

Machine Design

Fluid Mechanics

Thermodynamics

Casting

Joining of Materials

Metal Forming

Machine Tools and Machining

Metrology

Industrial Engineering